Our Insulated Shipping Container Liner Kits are the most cost effective method of protecting goods whilst in storage. They can also be used to protect perishable goods such as food, drinks and pharmaceutical products that require an ambient temperature during the cold chain transportation process.

All kits are supplied in made to measure rolls with adhesive backing ready to fit in position, making them easy to install. With each container liner insulation kit you also recieve Foil Joining Tape to seal all joints and edges.

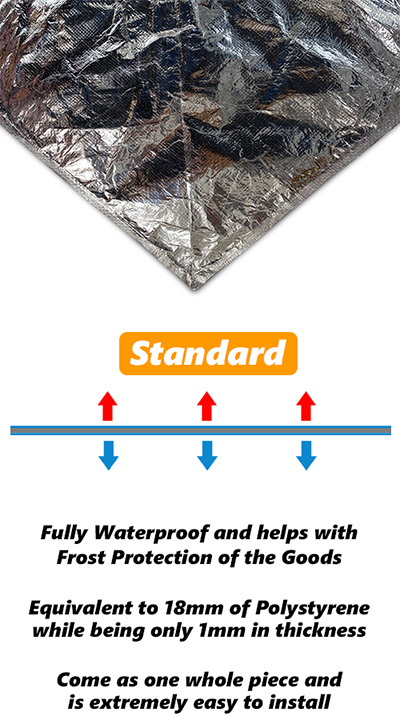

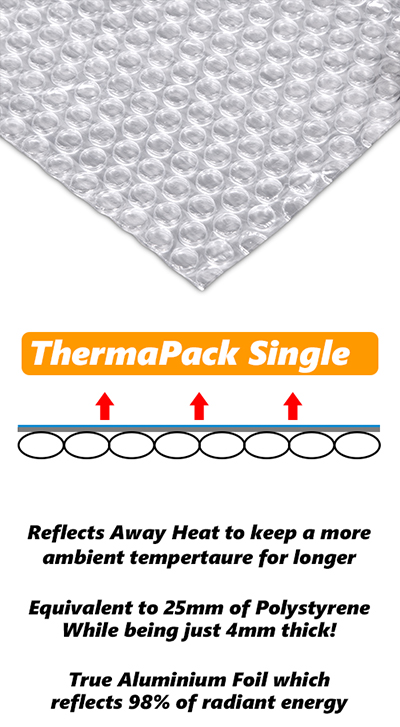

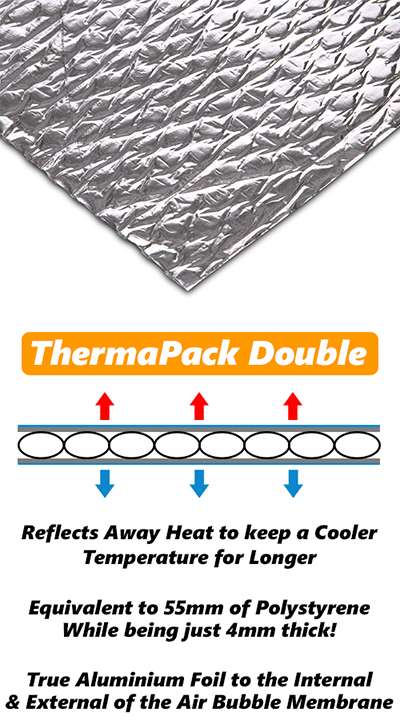

The Container Liner Kits can help reduce condensation due to their:

Vapour Barrier: Taping and sealing all overlaps and perimeter of the product enables it to work as an effective vapour control layer, stopping the passage of moisture.

Thermal Performance: The high thermal properties of the insulation reduce the thermal / cold bridging effect, from one side of the container to the other.

Reflective Thermal Cavities: Maintaining a cavity between the insulation and the steel container utilises radiant heat, not only increasing the overall thermal performance of the product, by further reducing the effect of thermal / cold bridging.

Our Container Liner Kits greatly reduce the risk of condensation, however, the level / source of condensation should be assessed prior to installation. Applications with high levels of moisture may require mechanical ventilation to reduce the risk of condensation. Roof only applications will only work by reflecting cold / heat away from the roof only.

You can order online or call our sales team on +47 973 44 456 to order.